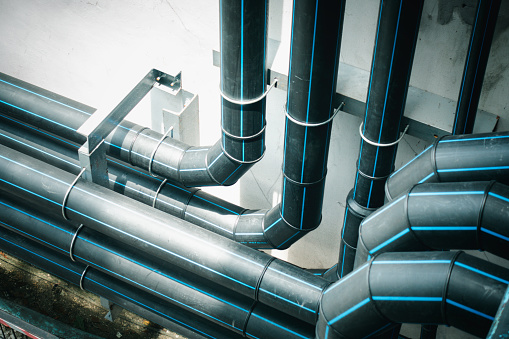

HDPE (High-Density Polyethylene Pipe fittings) is a specialized thermoplastic pipe made of melted and reformed material. It’s tough, adaptable, and long-lasting. Its resistance to chemical and environmental pressure is exceptional.

HDPE appears to be a novel product in comparison to current installations as ductile iron, concrete, or PVC. In actuality, it has been utilized in a wide range of piping systems for over five decades with great success.

HDPE pipe is an excellent choice for your plumbing systems because of thepoly pipe’s remarkable physical and performance characteristics.

Resistance to Corrosion

Rust is one of the issues that metal piping systems face. It impacts hydraulic efficiency both within and outside the pipe. Many communities treat their water to prevent rust and pitting in metal pipes, which is unavoidable. Others opt for expensive plastic coating, cathodic protection, and sleeving to extend the pipe’s service life.

Like conventional metal construction goods, HDPE pipes do not corrode, decay, or rust. It is unable to grow biologically. This translates to longer service life in lower long-term costs.

Resistance to Fatigue

HDPE pipe is not complicated but relatively flexible and malleable. It has exceptional fatigue resistance. It is built and pressure rated to manage intermittent and periodic surge occurrences that are typical in water distribution systems, unlike conventional plastic pipes.

Compared to other modes of plastic pipes, this will often allow you to use a thin wall HDPE pipe.

Service Life Extension

HDPE pipe is a secure and long-lasting option for your plumbing system. HDPE has a projected 50 to 100 years’ service life, resting on the requirements, design, and installation.

Joints That Don’t Leak

According to independent research, municipalitieslose a sufficient amount of their water owing to leakage joints.

Bell and spigot and the specialized mechanical type joints interconnect traditional infrastructure pipework, and all acknowledge a predetermined leakage fraction. Leaking pipes not only waste our most valuable resource, but they also cost our cities money. Heat fusion can fuse poly pipe systems, resulting in permanent leak-free couplings.

Joints that fuse to

Heat fusion welds can be used to link Polyethylene Pipefittings. Heat fusion is the process of fusing two HDPE surfaces to make a stable, monolithic, leak-free structure.

The fusion method for HDPE has been verified and utilized by the natural gas sector for over 40 years, unlike the fusion process established for other plastics pipes.

Fusing HDPE pipe is a simple process that can be taught to employees.

Adaptability

HDPE pipe can be linked using the Stab or Mechanical Fittings in addition to heat fusion.

These fittings come in various sizes and types to suit your pipe dimensions and application.

Mechanical Joint Adapters (MJ’s), Stab Fittings, or the Mechanical and Flanged Fittings make it simple to transition HDPE pipe to and from non-HDPE piping systems.

Installing Without Digging

Conventional piping systems can be installed using an open-cut method (digging a ditch), disrupting traffic and the environment. HDPE can be installed with the classic open-cut method or trenchless technology, which is more environmentally friendly.

A machine bores in horizontal directional deep in the earth for trenchless installation. The pipe is attached and dragged back through the hole after the drilling head comes to the end of the bore.